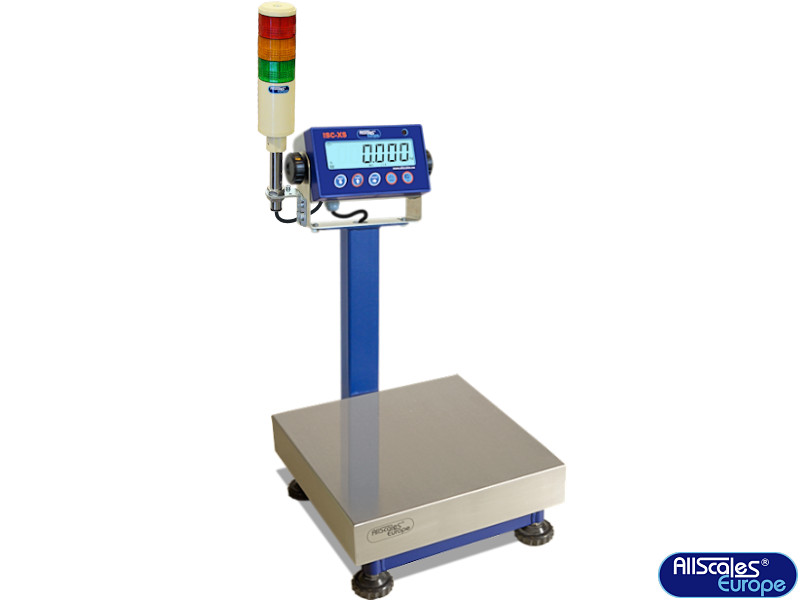

Checkweigher HM-Check-RVS

Checkweigher HM-Check-RVS, i.a. to be integrated into existing non-stop automatic chain conveyor production lines, with or without the dynamic determination of the target weight.

Full control of each product at the right weight, within set tolerances, without the intervention of staff.

Optionally equipped with ejector for products that fall outside the specified tolerances, or e.g.contain metal.

See further under Product information.

Checkweigher HM-Check-RVS

- compact, reliable and accurate checkweigher

- frame structure built in stainless steel

- equipped with front conveyor, weighing conveyor and ejection conveyor belt

- weighing capacity, number of belts / length / width and other performance according to your specific needs

- static or dynamic weighing

- weighing indicator HPR-Ultra integrated in stainless steel column: stainless steel housing, protection class IP68

- simple operation; water protected, 25-keys flat keyboard

- graphical backlit LCD-display, 25 mm height

- 16 clear LEDs indicating the active functions

- real time clock and alibi memory

- easy Excel data entry: direct communication to spreadsheet or word processing program on PC (like MSExcel or MSWord)

- switchable keyboard functions

- 15 configurable and printable ID-texts of 32 characters each, f.i. code, lot, operator ID, shift number, etc.

- permanent database of 500 articles with 2 lines of alphanumeric descriptions of 20 characters each, nominal weight, three +/- tolerance levels (T1, T2, T3), attached tare

- 4 levels of zero settable totals printable in an independent way: partial total, general total, grand total, total by article

- programmable printout from keyboard of 8 print formats linkable to various functions

- printing of article database with weights and pieces totals

- equipped with van emergency stop and start / restart button

- check function with easily adjustable tolerances highest and lowest weight

- statistics; memory for 1000 articles, with programmable alphanumeric description, density, tolerance limits, tare weight

- digital filters against vibration, airflow, vibrations etc.

- various lengths and versions are available

- power 230 V / 50 Hz

I/O SECTION

- 2 RS232 serial ports, for connection to printer, PC or PLC, radio module, and optional interfaces

- 1 RS232 serial port (or optional RS485), for connection to repeater, remote scale, badge reader

- fitted keyboard emulation input, for barcode/badge readers or external PC keyboard, through cable with mini DIN connector (optional)

Options: i.a.:

- RS-232 and RS-485 interface

- metal detector, with automatic ejection if metal is detected

- external thermal ticketprinter/labelprinter

- easy weigh software for Windows

- caster wheels under frame

- additional conveyor, etc.

Scale types: Checkweighers Application: Scales for Industry