Axle Weighing systems

There are two versions of axle weighing systems (static or dynamic weighing)

Both versions can be used to determine the weights of virtually all conventional vehicles.

Static: stops at every axle weighing

Static: stops at every axle weighing

Dynamic: keeps on driving at footpace (shorter weighing procedure)

By weighing axle weight and total weight trucks can be loaded correctly, whereby fines by the ILT (Inspectie Leefomgeving en Transport / Environment and Transport Inspectorate) for exceeded axle load or overcharging can be prevented.

Products: 12

-

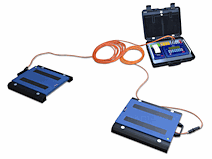

Static Axle Weighing System WAWXS (1 – 16 ton per axle) Consisting of 2 pcs weighing platforms (dimensions 400 x 300 mm), indicator and printer in carrying ...

Static Axle Weighing System WAWXS (1 – 16 ton per axle) Consisting of 2 pcs weighing platforms (dimensions 400 x 300 mm), indicator and printer in carrying ...

-

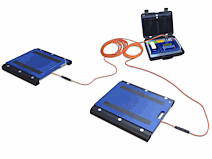

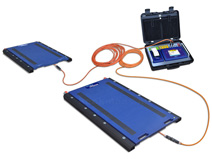

Static Axle Weighing System WAWS (up to 30 ton per axle) Consisting of 2 weighing platforms, dimensions 500 x 400 mm, 1 indicator with ticket printer in cary...

Static Axle Weighing System WAWS (up to 30 ton per axle) Consisting of 2 weighing platforms, dimensions 500 x 400 mm, 1 indicator with ticket printer in cary...

-

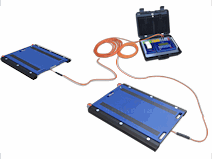

Static Axle Weighing System WAWM (up to 30 ton per axle) Consisting of 2 weighing platforms 450 x 700 mm, a weight indicator equipped with assembled ticke...

Static Axle Weighing System WAWM (up to 30 ton per axle) Consisting of 2 weighing platforms 450 x 700 mm, a weight indicator equipped with assembled ticke...

-

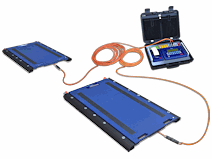

Static Axle Weighing System WAWL (up to 40 ton per axle) Consisting of 2 weighing platforms 500 x 900 mm, a weight indicator equipped with assembled ticketpr...

Static Axle Weighing System WAWL (up to 40 ton per axle) Consisting of 2 weighing platforms 500 x 900 mm, a weight indicator equipped with assembled ticketpr...

-

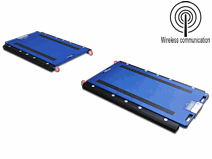

Wireless Static Axle Weighing System WAWS-RF (up to 30 ton per axle) Consisting of 2 weighing platforms 500 x 400 mm weighing surface, equipped with an integrated LCD-...

Wireless Static Axle Weighing System WAWS-RF (up to 30 ton per axle) Consisting of 2 weighing platforms 500 x 400 mm weighing surface, equipped with an integrated LCD-...

-

Wireless Static Axle Weighers WAWM-RF (up to 30 ton per axle) Consisting of 2 weighing platforms 450 x 750 mm, equipped with an integrated LCD-display enabling re...

Wireless Static Axle Weighers WAWM-RF (up to 30 ton per axle) Consisting of 2 weighing platforms 450 x 750 mm, equipped with an integrated LCD-display enabling re...

-

Wireless Static Axle Weighing System WAWL-RF (up to 30 ton per axle) Consisting of 2 wireless connected weighing platforms 500 x 950 mm, equipped with an integrated LCD-...

Wireless Static Axle Weighing System WAWL-RF (up to 30 ton per axle) Consisting of 2 wireless connected weighing platforms 500 x 950 mm, equipped with an integrated LCD-...

-

Dynamic Axle Weighing System DWA (up to 20 ton per axle) Dynamic Axle weighing system DWA for static or dynamic weighing of trucks, agricultural vehicles, et...

Dynamic Axle Weighing System DWA (up to 20 ton per axle) Dynamic Axle weighing system DWA for static or dynamic weighing of trucks, agricultural vehicles, et...

-

Dynamic axle weighing system WAWL-D (up to 40 ton per axle) Consisting of 2 weighing platforms 500 x 900 mm, a weight indicator equipped with assembled ticketpr...

Dynamic axle weighing system WAWL-D (up to 40 ton per axle) Consisting of 2 weighing platforms 500 x 900 mm, a weight indicator equipped with assembled ticketpr...

-

Dynamic Axle Weighing System WAWXL-D (up to 50 ton per axle) Consisting of 2 weighing platforms 900 x 700 mm, a weight indicator equipped with assembled ticketpr...

Dynamic Axle Weighing System WAWXL-D (up to 50 ton per axle) Consisting of 2 weighing platforms 900 x 700 mm, a weight indicator equipped with assembled ticketpr...

-

Axle weighing systems, special versions Our axle weighing systems are also available in special versions, tailored to your specific needs. O...

Axle weighing systems, special versions Our axle weighing systems are also available in special versions, tailored to your specific needs. O...

-

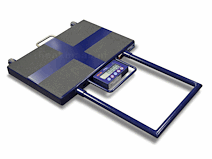

Pit Frames for Axle Weighing Platforms from the WAW-series

Set of 2 stove enamelled steel pit frames for axle weighing platforms WAWS, WAWM, WAWL, WAWL...

Pit Frames for Axle Weighing Platforms from the WAW-series

Set of 2 stove enamelled steel pit frames for axle weighing platforms WAWS, WAWM, WAWL, WAWL...