Checkweighers

Products: 6

-

Bench scales for checkweighing Bench scales for checkweighing: extensive “tailor made” versions concerning selection o...

Bench scales for checkweighing Bench scales for checkweighing: extensive “tailor made” versions concerning selection o...

-

Flower Check Weighing System

Flower check weighing system for 100% weight check on your flower bunches.

If a bunch weighs too lit...

Flower Check Weighing System

Flower check weighing system for 100% weight check on your flower bunches.

If a bunch weighs too lit...

-

Checkweigher HM-Check-RVS Checkweigher HM-Check-RVS, i.a. to be integrated into existing non-stop automatic chain conveyor pr...

Checkweigher HM-Check-RVS Checkweigher HM-Check-RVS, i.a. to be integrated into existing non-stop automatic chain conveyor pr...

-

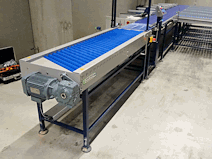

Package weighing / sorting system On this page you will find some images as an example of a parcel weighing/sorting system. Specificat...

Package weighing / sorting system On this page you will find some images as an example of a parcel weighing/sorting system. Specificat...

-

Checkweigher WPT-C-II Equipped with a clearly readable backlit LCD display, assembled on pole. Excellent price / performa...

Checkweigher WPT-C-II Equipped with a clearly readable backlit LCD display, assembled on pole. Excellent price / performa...

-

Checkweigher CW-100 Compact, reliable and accurate +/- checkweighing systems. Particularly suitable for integration in p...

Checkweigher CW-100 Compact, reliable and accurate +/- checkweighing systems. Particularly suitable for integration in p...